Understanding Cold Drawn Seamless Tubing: Key Insights for Construction and Decoration Professionals

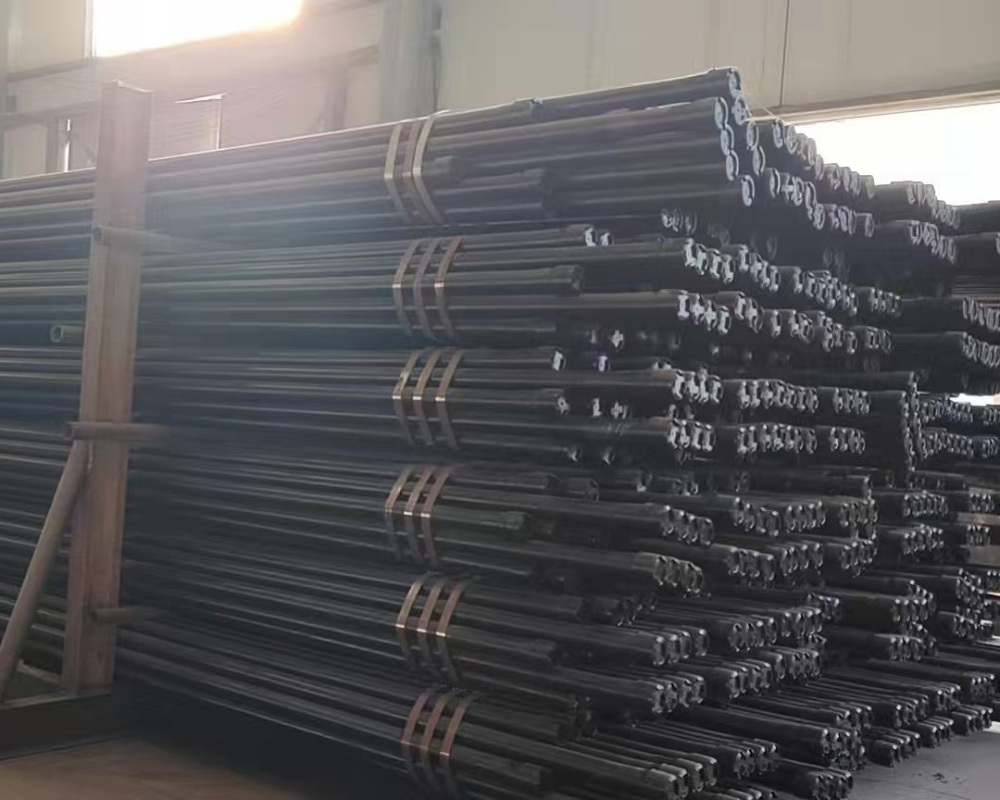

Cold drawn seamless tubing is a specific type of tubular product that is manufactured without any seams or welds, making it a preferred choice in many construction and decorative applications. The process of cold drawing involves pulling the tube through a series of dies at room temperature, which not only enhances its mechanical properties but also provides a superior surface finish.

One of the

Cold drawn seamless tubing is a specific type of tubular product that is manufactured without any seams or welds, making it a preferred choice in many construction and decorative applications. The process of cold drawing involves pulling the tube through a series of dies at room temperature, which not only enhances its mechanical properties but also provides a superior surface finish.

One of the primary advantages of cold drawn seamless tubing is its exceptional strength-to-weight ratio. As these tubes are produced without seams, they offer greater structural integrity compared to their welded counterparts. This characteristic makes them ideal for high-pressure applications, such as in hydraulic systems or structural components in buildings and installations. The ability to withstand high stress without risk of failure is critical in ensuring safety and longevity in construction projects.

Another significant benefit of cold drawn seamless tubing is its increased dimensional accuracy. The cold drawing process allows for precise control over the tube’s outer diameter and wall thickness, resulting in products that meet stringent specifications. This accuracy not only facilitates ease of installation but also helps in reducing material waste, ultimately contributing to cost-efficiency in projects.

When selecting cold drawn seamless tubing, professionals should consider the material from which it is made. Common materials include carbon steel, alloy steel, and stainless steel, each offering unique properties suited for different environments and uses. For instance, stainless steel tubing is resistant to corrosion and is often used in decorative applications where aesthetics and durability are paramount. On the other hand, carbon steel is favored for its strength and affordability in structural applications.

Additionally, it is essential to consider the tubing's compatibility with various fittings and connectors, as well as its ability to be manipulated for specific project needs. Cold drawn seamless tubing can be easily machined, bent, or formed to fit within a range of architectural designs, providing flexibility for innovative construction solutions.

In conclusion, cold drawn seamless tubing is a versatile and robust option in the construction and decorative materials industry. Its strength, accuracy, and adaptability make it an excellent choice for professionals looking to implement reliable solutions in their projects. By understanding the key attributes and applications of cold drawn seamless tubing, industry experts can make informed decisions that enhance the quality and efficiency of their work.

One of the primary advantages of cold drawn seamless tubing is its exceptional strength-to-weight ratio. As these tubes are produced without seams, they offer greater structural integrity compared to their welded counterparts. This characteristic makes them ideal for high-pressure applications, such as in hydraulic systems or structural components in buildings and installations. The ability to withstand high stress without risk of failure is critical in ensuring safety and longevity in construction projects.

Another significant benefit of cold drawn seamless tubing is its increased dimensional accuracy. The cold drawing process allows for precise control over the tube’s outer diameter and wall thickness, resulting in products that meet stringent specifications. This accuracy not only facilitates ease of installation but also helps in reducing material waste, ultimately contributing to cost-efficiency in projects.

When selecting cold drawn seamless tubing, professionals should consider the material from which it is made. Common materials include carbon steel, alloy steel, and stainless steel, each offering unique properties suited for different environments and uses. For instance, stainless steel tubing is resistant to corrosion and is often used in decorative applications where aesthetics and durability are paramount. On the other hand, carbon steel is favored for its strength and affordability in structural applications.

Additionally, it is essential to consider the tubing's compatibility with various fittings and connectors, as well as its ability to be manipulated for specific project needs. Cold drawn seamless tubing can be easily machined, bent, or formed to fit within a range of architectural designs, providing flexibility for innovative construction solutions.

In conclusion, cold drawn seamless tubing is a versatile and robust option in the construction and decorative materials industry. Its strength, accuracy, and adaptability make it an excellent choice for professionals looking to implement reliable solutions in their projects. By understanding the key attributes and applications of cold drawn seamless tubing, industry experts can make informed decisions that enhance the quality and efficiency of their work.

TAG:

Related Posts

Understanding Cold Drawn Seamless Tubing: Key Insights for Construction and Decoration Professionals

Cold drawn seamless tubing is a specific type of tubular product that is manufactured without any seams or welds, making it a preferred choice in many construction and decorative applications. The process of cold drawing involves pulling the tube through a series of dies at room temperature, which not only enhances its mechanical properties but also provides a superior surface finish.

One of the