Best Practices for Using Cold Drawn Seamless Tubing in Building Applications

Best Practices for Using Cold Drawn Seamless Tubing in Building Applications

Table of Contents

1. Introduction to Cold Drawn Seamless Tubing

2. Understanding Cold Drawn Seamless Tubing

3. Advantages of Cold Drawn Seamless Tubing in Construction

4. Applications of Cold Drawn Seamless Tubing in Building Projects

5. Best Practices for Implementing Cold Drawn Seamless Tubing

6

Best Practices for Using Cold Drawn Seamless Tubing in Building Applications

Table of Contents

- 1. Introduction to Cold Drawn Seamless Tubing

- 2. Understanding Cold Drawn Seamless Tubing

- 3. Advantages of Cold Drawn Seamless Tubing in Construction

- 4. Applications of Cold Drawn Seamless Tubing in Building Projects

- 5. Best Practices for Implementing Cold Drawn Seamless Tubing

- 6. Maintenance and Care for Cold Drawn Seamless Tubing

- 7. Environmental Considerations in Using Cold Drawn Seamless Tubing

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Cold Drawn Seamless Tubing

Cold drawn seamless tubing is revolutionizing the construction industry, providing a durable and versatile option for various applications. In this article, we explore the best practices for using this robust material in building projects. By understanding its properties, advantages, and proper implementation, you can ensure that your construction endeavors are both successful and sustainable.

2. Understanding Cold Drawn Seamless Tubing

Cold drawn seamless tubing is manufactured through a process that involves drawing hot metal over a mandrel, which creates a seamless tube. This method not only enhances the strength of the tubing but also ensures precise dimensions.

Key Characteristics of Cold Drawn Seamless Tubing

Cold drawn seamless tubing boasts numerous characteristics that make it suitable for construction:

- High Strength-to-Weight Ratio: This tubing is engineered to carry substantial loads while maintaining a lightweight profile.

- Corrosion Resistance: The seamless design minimizes the risk of corrosion, enhancing the longevity of the material.

- Precision Dimensions: The manufacturing process allows for tight tolerances and consistent wall thicknesses, ideal for various applications.

3. Advantages of Cold Drawn Seamless Tubing in Construction

The construction industry has widely embraced cold drawn seamless tubing due to its numerous advantages. Here are some of the key benefits:

Durability and Longevity

Cold drawn seamless tubing can withstand extreme conditions, making it an excellent choice for applications that require resilience. Its ability to resist impact, fatigue, and environmental degradation ensures that structures remain sound over time.

Cost-Effectiveness

While initial costs may be slightly higher than other materials, the durability and reduced maintenance needs of cold drawn seamless tubing can lead to long-term savings. This makes it an economical choice for large-scale projects.

Versatility

Cold drawn seamless tubing is versatile and can be used in various applications, including structural support, plumbing, and HVAC systems. Its adaptability allows architects and engineers to incorporate it seamlessly into their designs.

4. Applications of Cold Drawn Seamless Tubing in Building Projects

Cold drawn seamless tubing finds utility in numerous areas within construction. Here are some common applications:

Structural Frameworks

Utilizing cold drawn seamless tubing as part of the structural framework enhances rigidity and strength. Its lightweight nature allows for easier handling and installation, making it a popular choice among builders.

Plumbing and Piping Systems

The corrosion-resistant properties of cold drawn seamless tubing make it ideal for plumbing and piping systems. It can handle high-pressure applications, ensuring a safe and reliable supply of water and other fluids.

Mechanical and Electrical Applications

In mechanical and electrical systems, cold drawn seamless tubing provides a robust housing for cables and conduits, protecting them from damage while maintaining aesthetics.

5. Best Practices for Implementing Cold Drawn Seamless Tubing

To ensure the best outcomes in your construction projects, consider the following best practices for implementing cold drawn seamless tubing:

Proper Design Considerations

Before selecting cold drawn seamless tubing, conduct thorough design calculations to ensure that the tubing meets the required load-bearing capacities. Engaging with structural engineers can provide insights into the appropriate specifications needed for your project.

Quality Sourcing

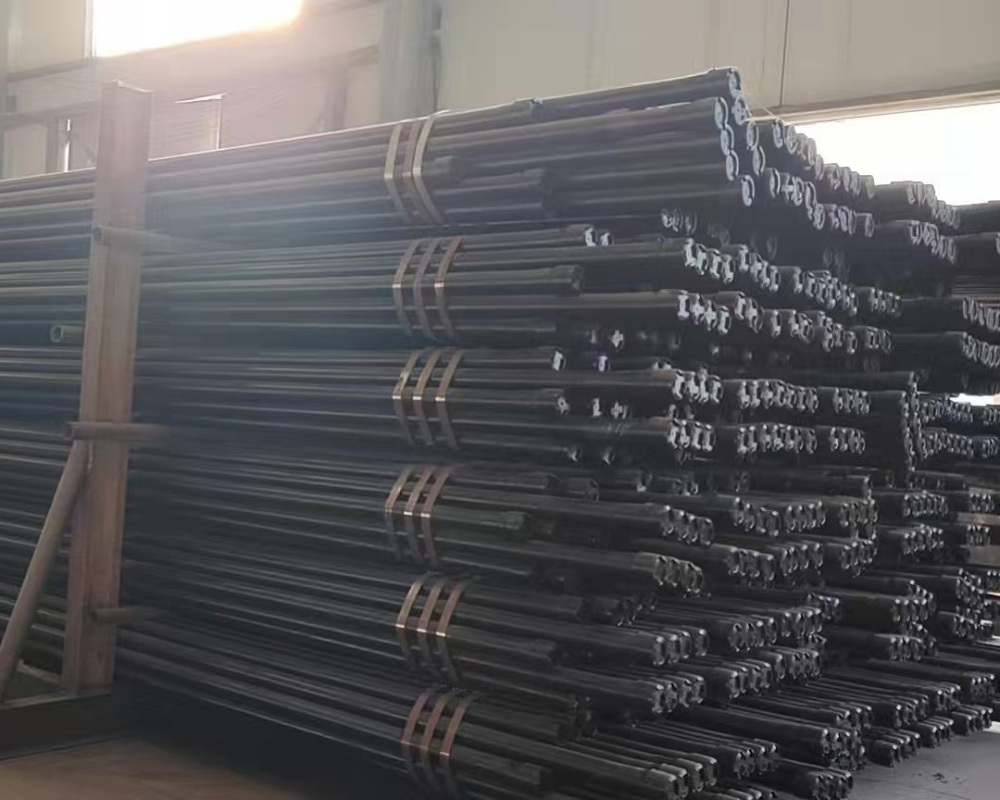

Select reputable suppliers who provide high-quality cold drawn seamless tubing that meets industry standards. Inspect materials upon delivery to ensure they are free from defects and consistent with specifications.

Correct Installation Techniques

Follow manufacturer guidelines for installation to avoid compromising the integrity of the tubing. Use appropriate methods for cutting, welding, and joining to maintain the seamless nature of the tubing.

6. Maintenance and Care for Cold Drawn Seamless Tubing

Ensuring the longevity of cold drawn seamless tubing in building applications involves regular maintenance and care:

Routine Inspections

Conduct routine inspections to identify any signs of wear, corrosion, or structural deficiencies. Early detection can prevent more substantial issues in the future.

Cleaning and Repair

Keep the tubing clean and free from debris. If any damage occurs, address repairs promptly to maintain the structural integrity and functionality of the tubing.

7. Environmental Considerations in Using Cold Drawn Seamless Tubing

Using cold drawn seamless tubing also presents environmental advantages:

Recyclability

Cold drawn seamless tubing can be recycled, reducing waste in landfills. Opting for recyclable materials aligns with sustainable construction practices.

Energy Efficiency

The durability and long lifespan of cold drawn seamless tubing contribute to energy efficiency in buildings. Structures that utilize high-quality materials may require fewer resources for heating and cooling.

8. Frequently Asked Questions (FAQs)

What is cold drawn seamless tubing used for?

Cold drawn seamless tubing is used in various applications, including structural support, plumbing, and HVAC systems due to its strength, durability, and versatility.

How does cold drawn seamless tubing differ from welded tubing?

Cold drawn seamless tubing is manufactured without any welds, making it stronger and more resistant to pressure and corrosion than welded tubing.

What are the main benefits of using cold drawn seamless tubing in construction?

Key benefits include high strength-to-weight ratio, corrosion resistance, durability, cost-effectiveness, and versatility in various applications.

Is there special maintenance required for cold drawn seamless tubing?

While cold drawn seamless tubing requires minimal maintenance, regular inspections and cleaning are essential to ensure longevity and prevent corrosion.

Can cold drawn seamless tubing be recycled?

Yes, cold drawn seamless tubing can be recycled, making it an environmentally friendly option in construction projects.

9. Conclusion

Incorporating cold drawn seamless tubing into building applications offers numerous advantages, from enhanced durability to cost-effectiveness. By following the best practices outlined in this guide, you can maximize the benefits of this versatile material in your construction projects. As the industry continues to evolve, embracing innovative materials like cold drawn seamless tubing will ensure that your structures stand the test of time while promoting sustainability.

TAG:

Related Posts

Understanding Cold Drawn Seamless Tubing: Key Insights for Construction and Decoration Professionals

Cold drawn seamless tubing is a specific type of tubular product that is manufactured without any seams or welds, making it a preferred choice in many construction and decorative applications. The process of cold drawing involves pulling the tube through a series of dies at room temperature, which not only enhances its mechanical properties but also provides a superior surface finish.

One of the